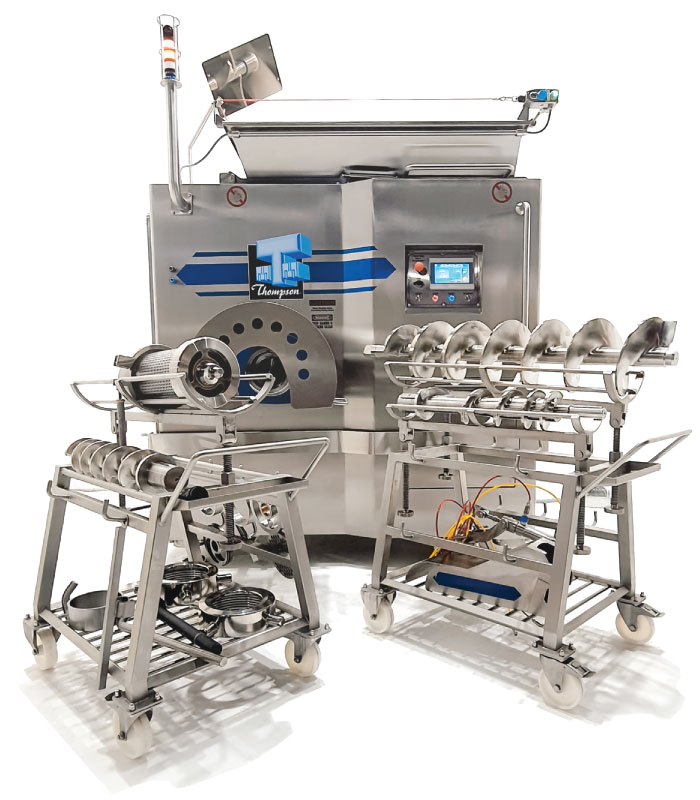

4300 Mixer Mincers

The 4000 mixing cycle is controlled by a factory “pre-set” or easily adjusted reciprocating mix cycle that achieves a well distributed particle mix for coarse ground high definition products or emulsified evenly seasoned products.

The standard cutting head on the 4000 Series is “56” (152 mm or 6″). The optional cutting heads are “66” (220 mm or 8 5/8″) or “GU” 160 double cut system. These cutting heads DELIVER HIGH PRODUCTION RATES to a variety of products from TEMPERED OR FLAKED FROZEN MEAT TO LIGHT FRESH MINCE.

Fed by feedscrew designs that have been mastered and evolved over a long history the Thompson 4000 delivers a constant feed to a cutting head that itself is at the cutting edge of technology – delivering a CLEAN CUTTING ACTION.

The mixing bowl and cutting head features all combine to offer a very HOMOGENEOUSLY MIXED PRODUCT with a high definition cut in short mix/mince cycles, therefore limiting heat rise to the product.

4300 Mixer Mincers

4000 Series

From the simple 3 push button machine as a standard – to optional degrees of control:

- Variable Speed Dial Control

- Programmable Pre-select Speed control

- Full Programmable Logic Control

GEMINI SYSTEMS The connection of two machines to incorporate a CONTINUOUS MINCING SYSTEM OR PROCESS.

The optional 66 size head

With the 66 Size head the OUTSTANDING PROCESSING PERFORMANCE and capabilities of the 4000 series machines are FURTHER IMPROVED.

The flared head design and the 8 5/8″ DIAMETER KNIVES AND PLATES of the 66 Size INCREASES PRODUCTION rates on fresh mince and sausage emulsions by as much as 20 % over the 56 Size head.

Production rates and the DEFINITION OF CUT IS IMPROVED and the 66 head is RECOMMENDED as a very favorable OPTION to a STANDARD 4000 Series machine when higher demands of processing are required.

THE 66 SIZE HEAD COMPLIMENTS THE POWERFUL MOTORS AND TOUGH DIRECT DRIVES OF THE 4000 SERIES OFFERING THE OPTION OF FURTHER GAINS IN MINCING CAPABILITIES.

Increasing the head size to 66 (8 5/8″) also assists in reducing cutting head pressures – reducing smearing possibilities and offering a very high definition of cut.