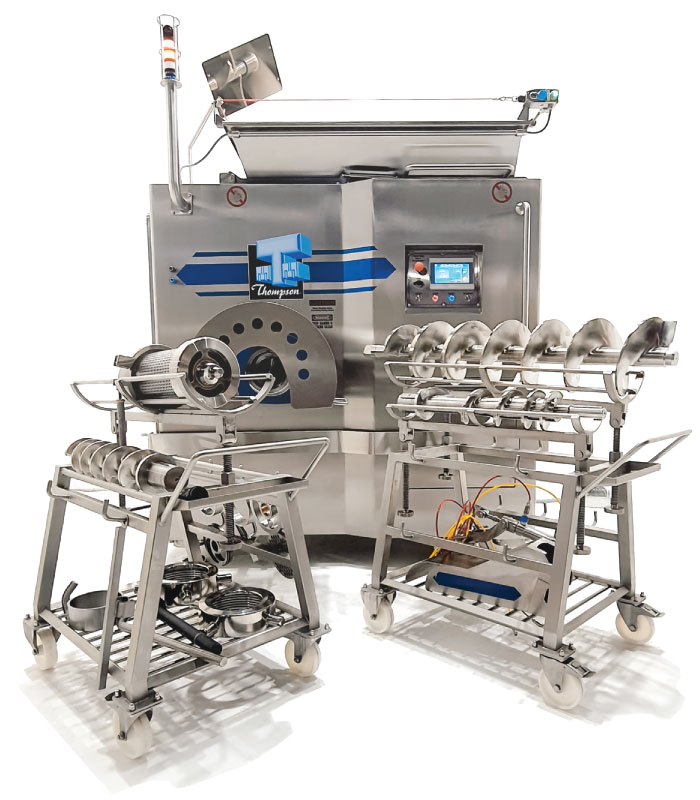

4200 Mixer Mincers

Used extensively in high production facilities throughout the World, the 4000 Series is renowned for its outstanding performance and reliability.

The standard height machines incorporate a HEAVY GAUGE DOMED LID with an open grilled section for ingredients adding or viewing of the mix cycle.

An ingredients or liquids pouring channel is also offered as an option.

The MIXING PADDLE AND MINCE TRANSMISSION are powered with INDEPENDENT GEARED MOTOR DRIVES. No more oily greasy chains, no more continual maintenance of pulleys and belt drives.

Smooth, compact and quiet the HEAVY DUTY DRIVES are very efficient in transmitting maximum power from LARGE HP MOTORS – featuring a STANDARD 2 SPEEDS on the feedscrew drive with HIGH TORQUE on low speed.

4200 Mixer Mincers

4000 Series

Connecting a Primary Mixer Mincer for the first mince operation which then AUTOMATICALLY FEEDS THROUGH AN INTERCONNECTED TUBE to the Secondary Mixer Mincer for continuous processing of the second mince operation.

Product transfer is achieved through a guarded interconnecting tube, by a safety interlocked transfer tube or a combination of both.

The machines can also be easily separated in the event that different processing applications may be required i.e. batching of formulated product or emulsions.

The Gemini system allows Thompson 4000 Series Mixer Mincers to be connected in tandem with multiple machines including non Thompson machines.

THE ADVANTAGES FROM UTILISING GEMINI SYSTEMS for continuous mincing can include REDUCED CAPITAL EQUIPMENT COST from eliminating second mechanical loading hoist or device, LABOUR COST SAVINGS from improved operation efficiencies in production and IMPROVED PRODUCT QUALITY by eliminating product storage and processing time during the 1st and 2nd mincing operations.

Models in the series include

- 4000-56 standard or raised machine – 200 L bowl 56 Size cutting head

- 4200-56 standard or raised machine – 300 L bowl 56 Size cutting head

- 4300-56 standard or raised machine – 400 L bowl 56 Size cutting head

- 4200 FROZEN-56 standard or raised machine – 350 L bowl 56 Size cutting head